Advantages of our services

WHAT IS MOORING MASTER SERVICE? OUTSOURCE OR SELF-TRAINING?

There are some good reasons to answer these questions:

- 1- “Right Person for the Right Job”: Berthing, mooring, unberthing, offloading hose transfer, loading operation need a high degree of local experience and a highly trained person dedicated for these purposes. A Mooring Master who has a background of skillful pilot and long experience in Oil Industry can excellently accomplish this job in a safest and most economical manner. This is All-in-One solution where a Mooring Master can serve as a reliable Pilot, a Tanker Inspector, a professional Loading Master and Terminal Representative who can complete documentation and supervise all offtake activities carried out within safe parameters associated with high standards of Terminal Regulations, OCIMF, SIGTTO… So far, our Mooring Masters have been completing more than 1,000 safe offtakes in almost all Terminals of Viet Nam. The Client’s satisfaction is our pride and reputation of our devoted work.

- 2- Saving cost: Some giant Oil Majors often train their own Mooring Masters for this purpose, but let’s consider all expenditure for recruitment, training, paying significant salary, insurance … to the right persons if any (note that ”the right person for the right job”) . It might not be a matter with big companies where human resource is available, but how about small Terminal Operators who do not have offtake operations frequently? Maybe, a professional Mooring Master Service outsourcing is a better solution? It can minimize cost for you.

- 3- Experience: All of our Mooring Masters were over 20 year-experience Pilots, and carefully selected from the best Pilots in Viet Nam so the shiphandling skill is not only our daily job but a nature of instinct as well. Our Mooring Master were also highly-trained and worked for some world-class Oil Companies for over 10 years and have experience of over 1000 safe offtakes in various type of installations and jobs (tandem, STS, SBM, spread-moor, dry-docking, towing, rig moving …) in many patterns of weather. It’s “practice makes perfect” skill through experience.

- 4- Flexibility: We can provide many types of service for tandem mooring, STS transfer, SBM mooring, spread mooring, towing assistance, rig mover assistance … in long-term, short-term or ad hoc contract at competitive charge.

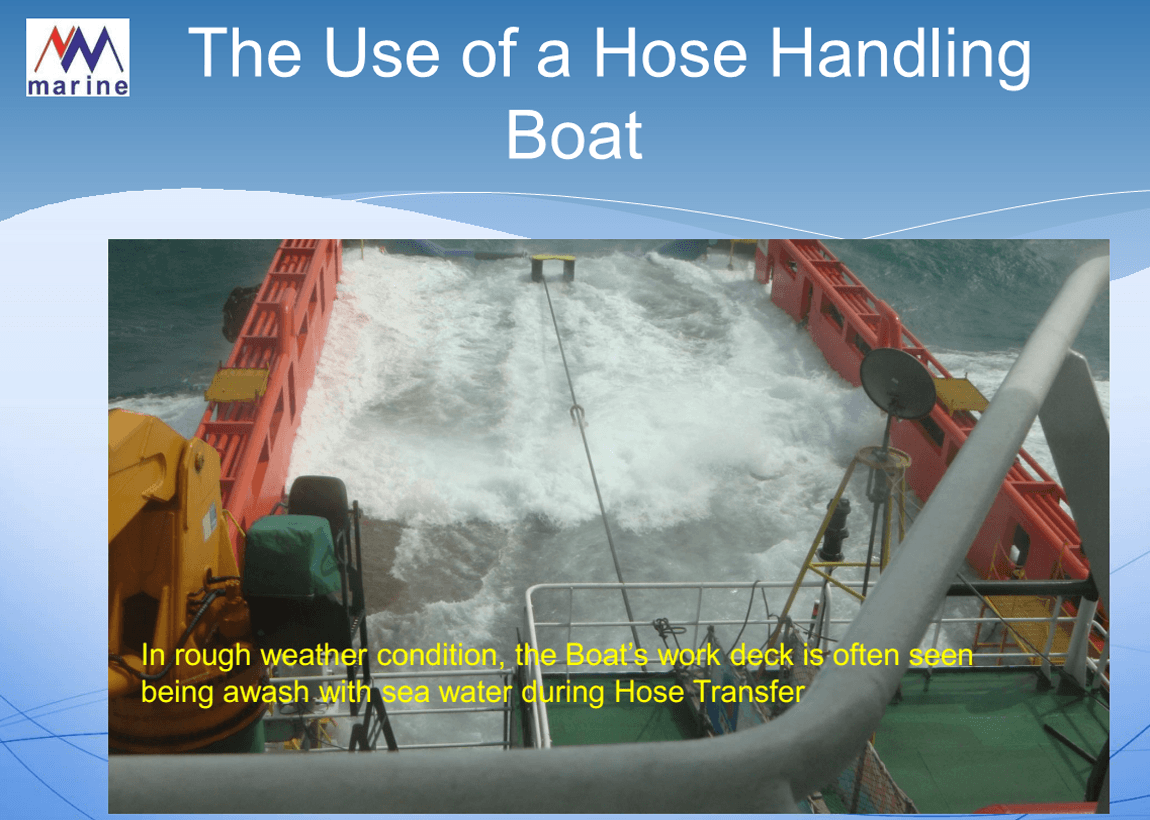

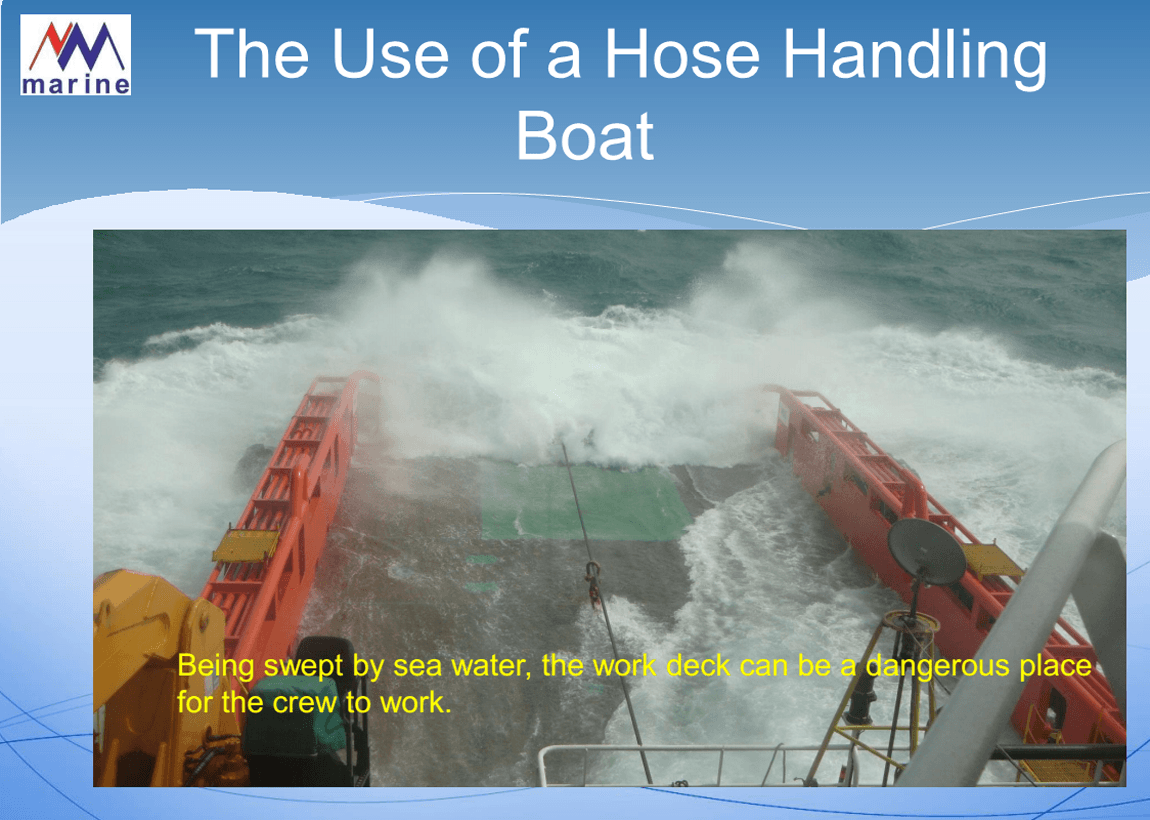

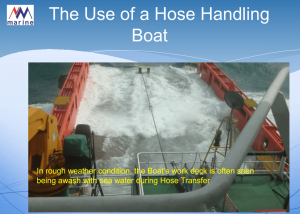

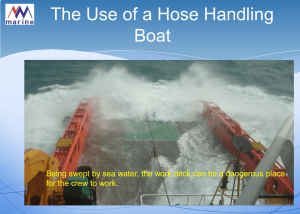

HOSE TRANFER BY ROPE OR “BOATLESS TRANSFER” IN LIFTING OPERATIONS

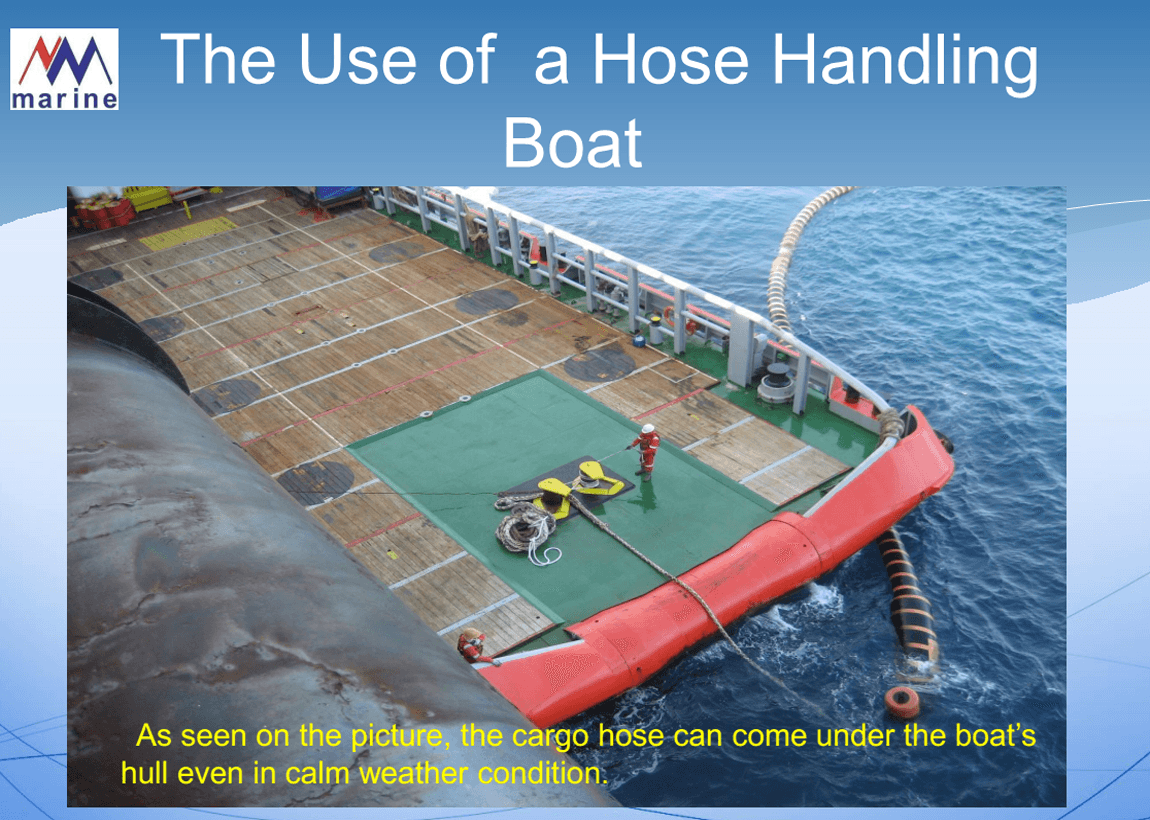

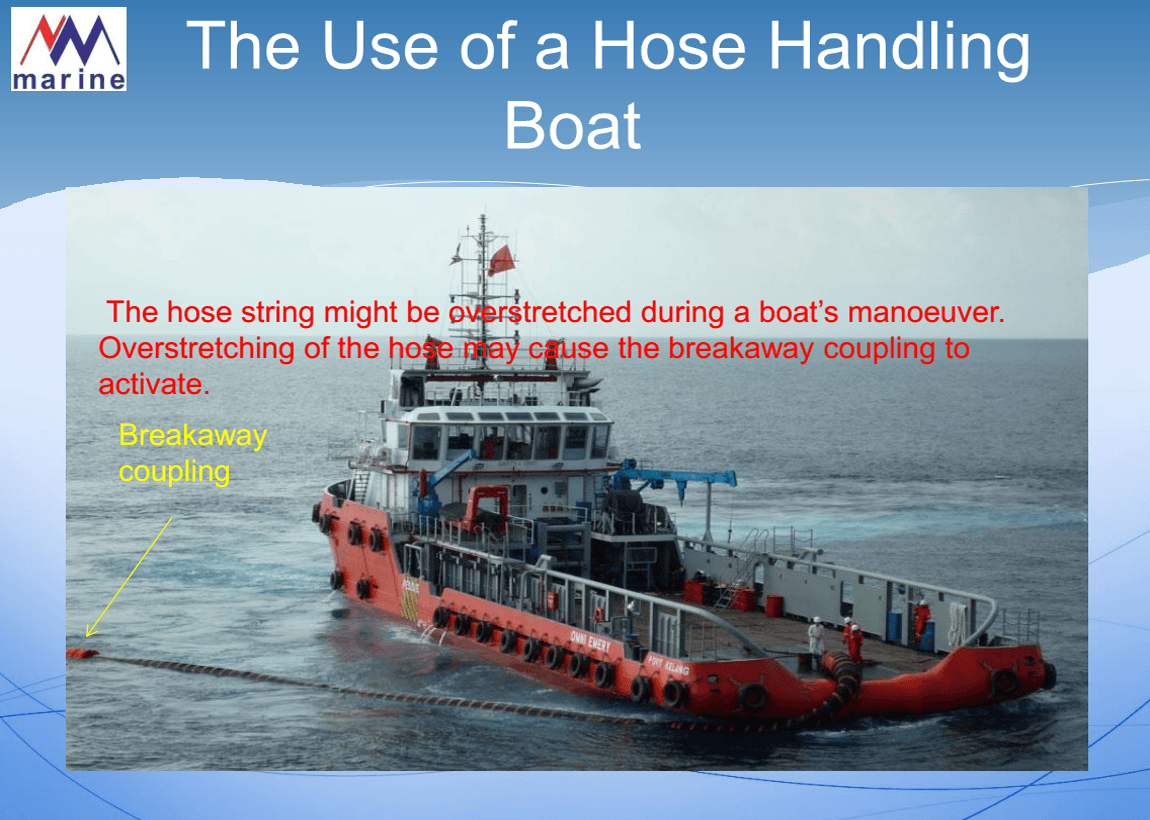

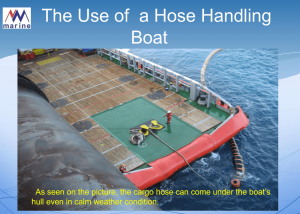

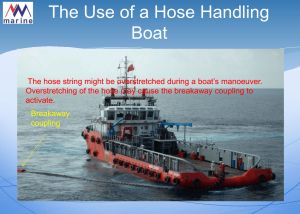

In the East Sea of Viet Nam, the weather is subject to South West and North East monsoon where gusts of NE monsoon can extent to 30-50kts, sea state from 5-8m in weeks (see illustration). The most concern of all Terminals Operator is the threat of tank-top that is no vacuum in the tanks on FP(S)Os that oil production activities may be temporarily shut-downed to prevent over-filling. Let’s figure out in a Terminal like Su Tu Den or Te Giac Trang, there are 5 to 6 offtakes/month (particularly, sometimes 9 offtakes/month for 1 FPSO), the lifting schedule is really close so there is no time for mistake. A day of suspension can cost millions of US dollars combined with many problems which might arise while restarting production. One of the most vulnerable activities that can harm the whole smooth operation is the transfer crude oil from F(P)SO to Export Tanker which are associated with berthing Export Tanker to F(P)SO, transfer hose from F(P)SO to Export Tanker, hose handling… Normally at other Terminals, a second supply boat is utilized to do this job (while the first one is in static tow with Export Tanker in tandem mooring). In bad weather it has been found that hose handling & hose transfer is most sensitive to sea and swell conditions where the human factor, hose handling experience of the supply boat’s Captain, tug’s characteristic and availability strongly affect the operation.

Since 2004, our Mooring Master were the pioneers in developing, utilizing and further improving a new method of hose transfer without using second supply boat, the so-called ‘Boatless Cargo Hose Transfer’. This method is less dependent on supply boats and proven remarkably safer to personnel on supply boat, more effective and economical than the conventional way. Through more than 10 years of practicing, improving and sharpening, we have a vast experience in doing this job. So far, we have been passing more than 1000 safe offtakes at many Terminals in Viet Nam with minimum delays. Many Oil Field Operators have admitted that it is a safest and most cost-effective method where a cargo hose string can be transferred safely to Export Tanker in a larger extent of weather conditions. Understandably, almost all of Terminals in Viet Nam nowadays do apply this method for hose transfer operation.